院士科创发展.长城 联合 氢能检测

中心概况

2018年6月开始运行的氢能检测中心是目前世界领先、国内首座大型氢能、燃料电池汽车关键组件综合型研发检测中心。建设总投资约 5.7 亿元人民币,为国内最具优势的检测中心。其中105MPa氢循环测试、燃料电池系统测试、动力总成测试为国内最优质的测试资源。

目前,检测中心现已吸纳各类关键人才 105 名,其中行业顶尖外籍专家 19 人,硕士以上学历占比 80% 以上。现拥有标准试验室 12 个,共引进国际各类高尖端设备 240 余台,在储氢安全性,燃料电池、系统性能,整车性能等领域具备近百项检测能力。

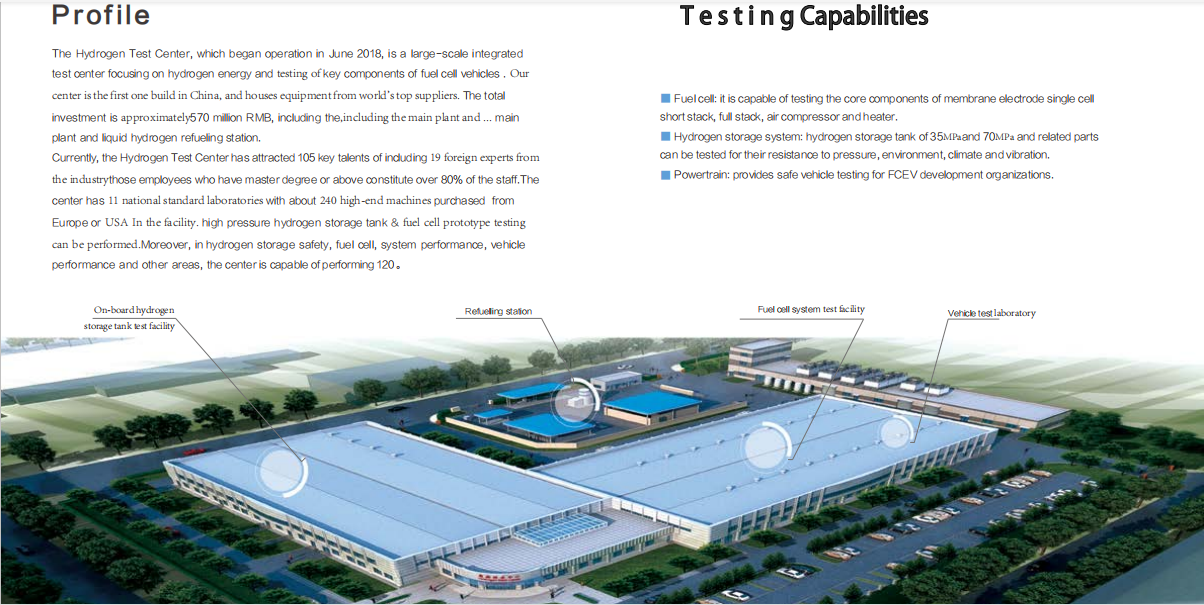

Profile

The Hydrogen Test Center, which began operation in June 2018, is a large-scale integrated test center focusing on hydrogen energy and testing of key components of fuel cell vehicles . Our center is the first one build in China, and houses equipment from world's top suppliers. The total investment is approximately570 million RMB, including the main plant and liquid hydrogen refueling station.

Currently, the Hydrogen Test Center has attracted 105 key talents of including 19 foreign experts from the industrythose employees who have master degree or above constitute over 80% of the staff.The center has 12 national standard laboratories with about 240 high-end machines purchased from Europe or USA In the facility. high pressure hydrogen storage tank & fuel cell prototype testing can be performed.Moreover, in hydrogen storage safety, fuel cell, system performance, vehicle performance and other areas, the center is capable of performing 120

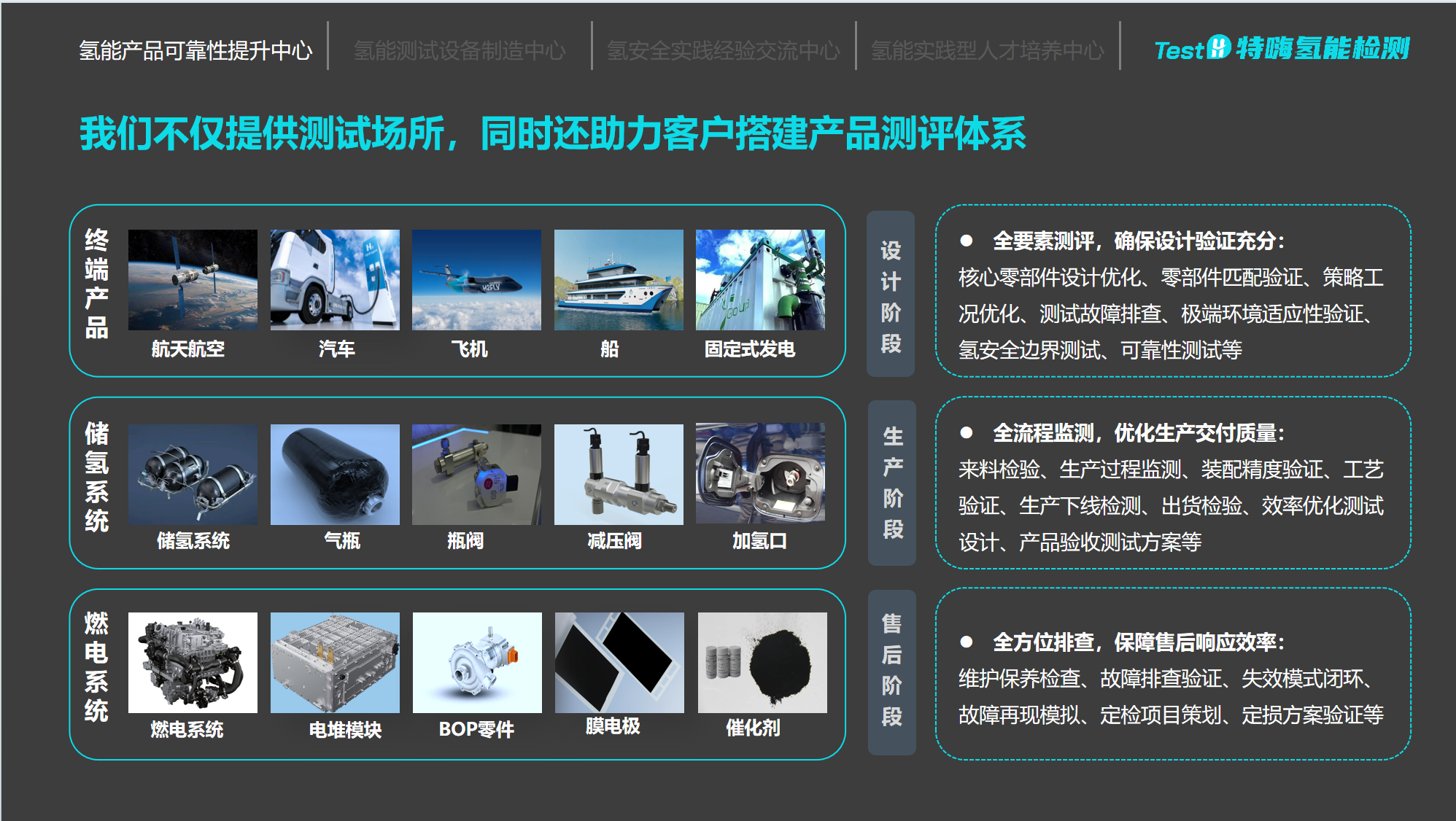

测试能力

1 燃料电池方面:具备对膜电极单电池、短堆、长堆、空压机、加温器等核心零部件全系列检测能力。

2 储氢系统:可实施 35MPa、70MPa 储氢瓶及相关零部件耐压力、耐环境气候、耐振动等测试。

3 动力总成:为 FCEV 研发机构提供安全的整车测试。

Testing Capabilities

1, Fuel cell: it is capable of testing the core components of membrane electrode single cell, short stack, full stack, air compressor and heater.

2, Hydrogen storage system: hydrogen storage tank of 35MPaand 70MPa and related parts can be tested for their resistance to pressure, environment, climate and vibration.

3, Powertrain: provides safe vehicle testing for FCEV development organizations.

燃料电池模块

Fuel Cell Module Test Facility

燃料电池测试室主要包含 G40/ G60 单体测试站、G100/G400/G500 堆栈测试站、G900 大功率堆栈测试站及配套 GAMRY、HIOKI 等测试设备。进行单体、堆栈的活化极化测试,开展过量系数、压力、温度湿度等敏感度测试,完成耐久性能测试等

Fuel Cell Module

The fuel cell test room features G40/ G60 unit test stations, G100/G400/G500 stack test stations, G900 high-power stack test stations and supporting GAMRY, HIOKI and other test equipment.Possible tests include activation polarization test of monomer and stack, conduct sensitivity test of excess coefficient, pressure, temperature and humidity, and complete durability test

单体燃料电池测试

FC single cell test

单体电池测试:引进国际顶级设备供应商 G40、G60、G100 单体测试站共 24 台,测试功率范围为 0-1kW,主要用于膜电极的性能测试,可实现对温度、相对湿度、压力、流量、电流等参数的精确控制,电压的实时监测,实验数据的实时记录,能够配备 HIOKI、Gamry 等辅助测试设备完成对膜电极性能指标验证的全系列测试任务。

FC single cell test

Single cell: equipped with international top hardware of G40, G60 and G100 totalling 24 test stations, ranging from 0 to 1kW. These are mainly used for the performance test of membrane electrode assembly. Throughout the process we are able to accurately control temperature, relative humidity, pressure, flow rate and current, monitoring voltage and remove the word other parameters in real time and realizing data records. Meanwhile all of test stations are set up with HIOKI, Gamry and other auxiliary devices that help with complete validation of full range of testing tasks.

燃料电池短堆测试

FC short stack test

短堆测试:引进短堆测试站 G400、G500 共 10 台,测试功率可达 10kW,主要用于短堆的性能分析测试,包括高、低温极化测试,阴、阳极敏感度测试等,期间可实现单片电池电压的实时监测(最多 40 片),异常报警及处理;可配合环境试验箱完成短堆的低温存储、低温启动等试验,其中环境箱温度控制范围为 -70℃ -180℃,湿度 0-95%RH(无负载,10-85℃),可满足所有燃料电池短堆测试试验的环境要求。

FC short stack test

Short stack: 10 test stations (G400 and G500) with test power rate up to 10kW.They are mainly used for performance analysis of short stacks, including high and low temperature polarization test, negative and anode sensitivity test, etc. With the real time monitoring of single cell voltage (up to 40pieces), it is able to trigger abnormal alarm and realize instant treatment. The low-temperature storage and start-up tests of short stacks are completed in an environmental chamber.It has temperature control range from -70℃ -180℃ , and the humidity0-95% RH (when has no load, 10-85℃ ). The lab meets the environmental requirements of all fuel cell short stack tests.

整堆电池测试

FC full stack test

试验室引进 G900 大功率堆栈测试站、步入式环境箱、电堆泄漏测试装置等,可完成整堆泄漏测试、保压测试、极化性能测试、稳定性测试、耐久性测试、低温启停测试等全系列测试任务,测试最大功率可达 125kW,可实现温湿度、压力、流量等实验条件的精确控制,能满足客户各种实验条件需求。

FC full stack test

Our laboratory features G900 high-power test station,step-in environment chamber,leak test equipment,etc.We can complete leak test,

燃料电池汽车动力总成测试

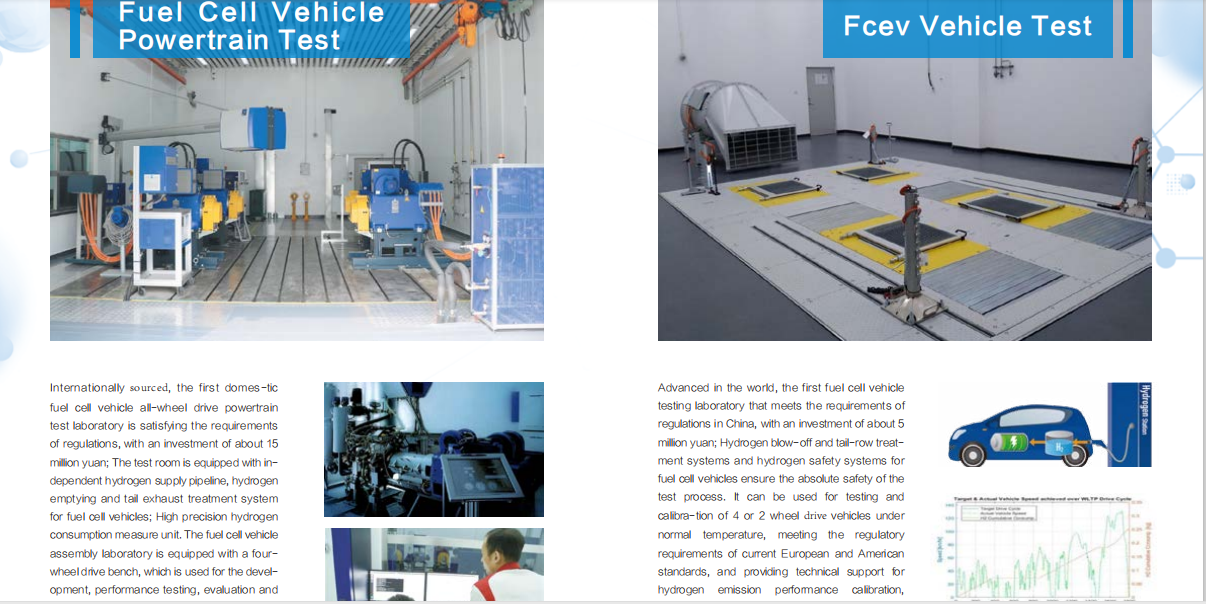

Fuel Cell Vehicle Powertrain Test

国际先进,国内首家符合法规要求的燃料电池整车四驱动力总成测试试验室,投资约 1500余万元;试验室内具备独立供氢管路,燃料电池汽车专用的氢气放空和尾排处理系统;具备高精度的氢气消耗量计量单元。燃料电池汽车总成试验室配备四驱台架,用于燃料电池汽车的动力总成开发、性能测试、评价与研究,缩短整车及动力总成的开发周期。

Fuel Cell Vehicle Powertrain Test

Internationally sourced, the first domes-tic fuel cell vehicle all-wheel drive powertrain test laboratory is satisfying the requirements of regulations, with an investment of about 15 million RMB; The test room is equipped with independent hydrogen supply pipeline, hydrogen emptying and tail exhaust treatment system for fuel cell vehicles; High precision hydrogen consumption measure unit. The fuel cell vehicle assembly laboratory is equipped with a fourwheel drive bench, which is used for the development, performance testing, evaluation and research of the fuel cell vehicle’s powertrain to shorten the development period of the vehicle and its systems.

燃料电池汽车整车测试

Fcev Vehicle Test

国际先进,国内首家符合法规要求的燃料电池整车测试试验室,投资约 500 余万元;燃料电池汽车专用的氢气放空、尾排处理系统及试验室氢气安全系统,保证测试过程的绝对安全。可用于 4驱或 2 驱车辆在常温下的工况测试与标定,满足现行欧洲及美标标准的法规要求,为整车氢气排放性能标定、能量消耗量和续驶里程测试、车辆动力性能与氢气消耗性能评估提供技术支持

Fcev Vehicle Test

Advanced in the world, the first fuel cell vehicle testing laboratory that meets the requirements of regulations in China, with an investment of about 5 million yuan; Hydrogen blow-off and tail-row treatment systems and hydrogen safety systems for fuel cell vehicles ensure the absolute safety of the test process. It can be used for testing and calibra-tion of 4 or 2 wheel drive vehicles under normal temperature, meeting the regulatory requirements of current European and American standards, and providing technical support for hydrogen emission performance calibration, energy consumption and driving range testing,vehicle dynamic performance and hydrogen consumption performance evalua-tion.

储氢系统模块

Hydrogen Storage System Test Facility

拥有四大国家级标准试验室:环境试验室、环境振动试验室、液压疲劳爆破及脉冲试验室、高压氢气循环及储氢系统试验室,各试验室均引进多套欧美高尖端设备,具备总成级测试能力和材料、零部件级测试能力,应用领域广泛,可满足多项行业测试标准。

Hydrogen Storage System Test Facility

It has four national standard laboratories: environmental laboratory, environmental vibration laboratory, hydraulic fatigue blasting and pulse impact laboratory, high-pressure hydrogen circulation and hydrogen storage system laboratory all introduce several sets of advanced equipment from Europe and America. Here we have the assembly level test ability and the material, the spare parts level test ability, the application domain is widespread, may satisfy many industy test standard

高低温及理化试验室

High and low temperature and physical and chemical laboratory

高低温及理化试验室 由温湿度试验室和盐雾腐蚀试验室组成。

温湿度试验室:配备 5 台高低温湿热试验箱和 1 台冷热冲击试验箱,用于测试储氢部件在可变的气候条件下的可靠性及耐气候性能。

盐雾腐蚀试验室:配备一台复合式盐雾试验箱,能模拟汽车在道路行驶期间受到盐等化学物质的影响,以此测试储氢部件的抗腐蚀耐久性。

高低温湿热试验箱

冷热冲击试验箱

复合式盐雾试验箱

High and low temperature and physical and chemical laboratory

The temperature and physical-chemistry laboratory is composed of temperature and humidity and salt spray corrosion test room.

Temperature and humidity laboratory: equipped with 5 high and low temperature humidity and heat test Chambers and 1 thermal shock test chamber, it is used to test the reliability and weather resistance of hydrogen storage parts under variable climatic conditions.

Salt spray corrosion test chamber: equipped with a compound salt spray test chamber, it can simulate the impact of salt and other chemicals on the vehicle during road driving, so as to test the corrosion resistance durability of hydrogen storage components.

High and low temperature wet heat test chamber

Thermal shock test chamber

Compound salt spray test chamber

环境振动试验室

Climatized Vibration & Shock Testing Lab

环境振动试验室配备一台用于测试车载零部件的 2T 三综合振动试验台以及一台用于测试储氢瓶和完整的储氢系统的 20T 振动试验台。其能够通过随机或周期振动、冲击试验来检测储氢部件和整个系统的可靠耐久性、失效模式分析;拥有共振检测模式,从而确定关键零部件和储氢系统的共振频率。另外,三综合环境振动台可以在不同温度范围 (-50℃∽ +150℃ ) 和不同湿度范围内 (20% ∽ 98%@T > 20+℃ ),或者独立的进行振动和冲击试验。

20T 振动试验系统

2T 三综合振动试验系统

Vibration & Shock Testing Lab

Vibration & Shock Testing laboratory is equipped with two electrodynamic shakers:electrodynamic shaker (2T) for hydrogen storage components and a high payload electrodynamic shaker (20T) for hydro-gen storage tank and complete storage system. The shakers can be used to investigate the durability, failure and performance effects arising from vibrational excitation (random and periodic) and shock on hydrogen storage components and system. The shakers also feature a resonance sweep mode to identify the resonant frequency of components and the hydrogen storage system. The component electrodynamic shaker allows the investigation of the vibration and shock on the performance simulta-neously and independently under varying temperaturesbetween -50℃ and +150℃ and relative humidity of 20%-98% (@ T >20+℃ ).

20T Vibration test system

2T Comprehensive vibration test system

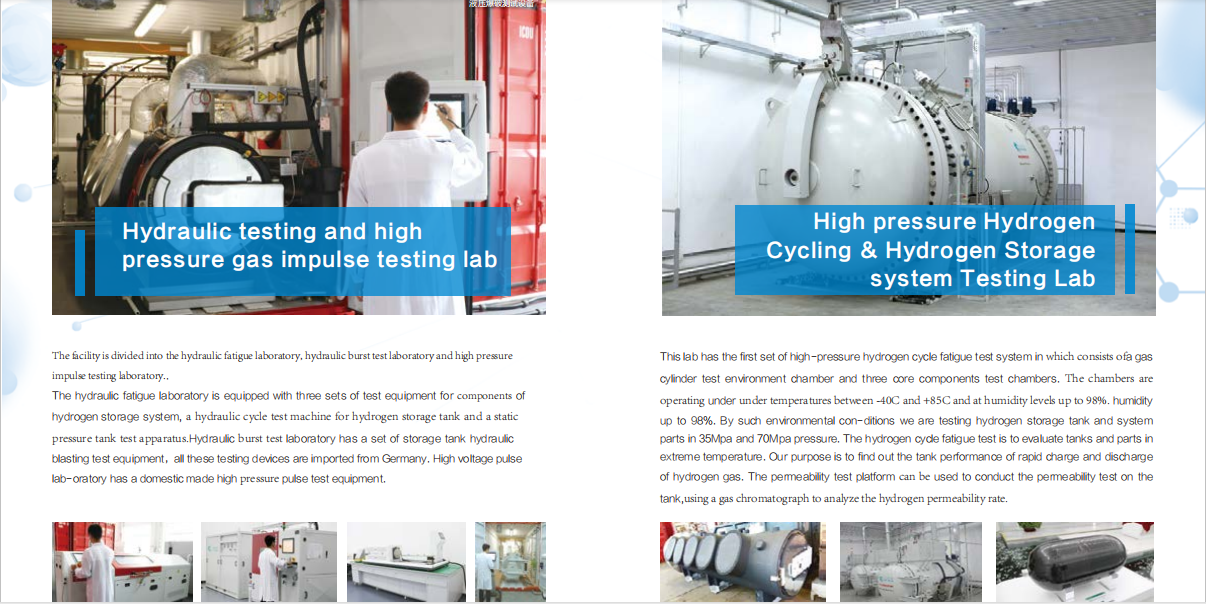

液压测试及高压脉冲试验室

Hydraulic testing and high pressure gas impulse testing lab

液压测试及高压脉冲试验室 分为液压疲劳试验室、液压爆破试验室、高压脉冲试验室。

其中液压疲劳试验室配备三套德国进口储氢系统零部件测试设备,一套德国进口储氢罐液压循环测试设备、一套静压测试设备;液压爆破试验室拥有一套德国进口储氢罐液压爆破测试设备;高压脉冲试验室拥有国产高压脉冲测试设备一台。

液压疲劳

液压爆破测试设备

高压脉冲试验系统

高温烤箱

静压测试设备

Hydraulic testing and high pressure gas impulse testing lab

The facility is divided into the hydraulic fatigue laboratory, hydraulic burst test laboratory and high pressure impulse testing laboratory.

The hydraulic fatigue laboratory is equipped with three sets of test equipment for components of hydrogen storage system, a hydraulic cycle test machine for hydrogen storage tank and a static pressure tank test apparatus.Hydraulic burst test laboratory has a set of storage tank hydraulic blasting test equipment,all these testing devices are imported from Germany. High voltage pulse lab-oratory has a domestic made high pressure pulse test equipment.

高压氢气循环及储氢系统试验室

High pressure Hydrogen Cycling & Hydrogen Storage system Testing Lab

高压氢气循环及储氢系统试验室 拥有国内第一套高压氢气循环疲劳试验系统,由一个气瓶测试环境仓和三个核心零部件测试环境仓组成, 仓内温控范围为 -40℃ ~+85℃,湿度最高可达 98%,可在低温或高温高湿度环境下对对储氢瓶以及储氢系统核心零部件进行 35MPa 或 70MPa的高压氢气循环疲劳试验,去评估在极端温度环境下,储氢瓶和部件快速重放氢气的性能。并可以使用渗透试验测试平台,对气瓶进行渗透试验,通过气相谱仪分析气瓶渗透情况。

High pressure Hydrogen Cycling & Hydrogen Storage system Testing Lab

This lab has the first set of high-pressure hydrogen cycle fatigue test system in which consists ofa gas cylinder test environment chamber and three core components test chambers. The chambers are operating under under temperatures between -40C and +85C and at humidity levels up to 98%. humidity up to 98%. By such environmental con-ditions we are testing hydrogen storage tank and system parts in 35Mpa and 70Mpa pressure. The hydrogen cycle fatigue test is to evaluate tanks and parts in extreme temperature. Our purpose is to find out the tank performance of rapid charge and discharge of hydrogen gas. The permeability test platform can be used to conduct the permeability test on the tank,using a gas chromatograph to analyze the hydrogen permeability rate.

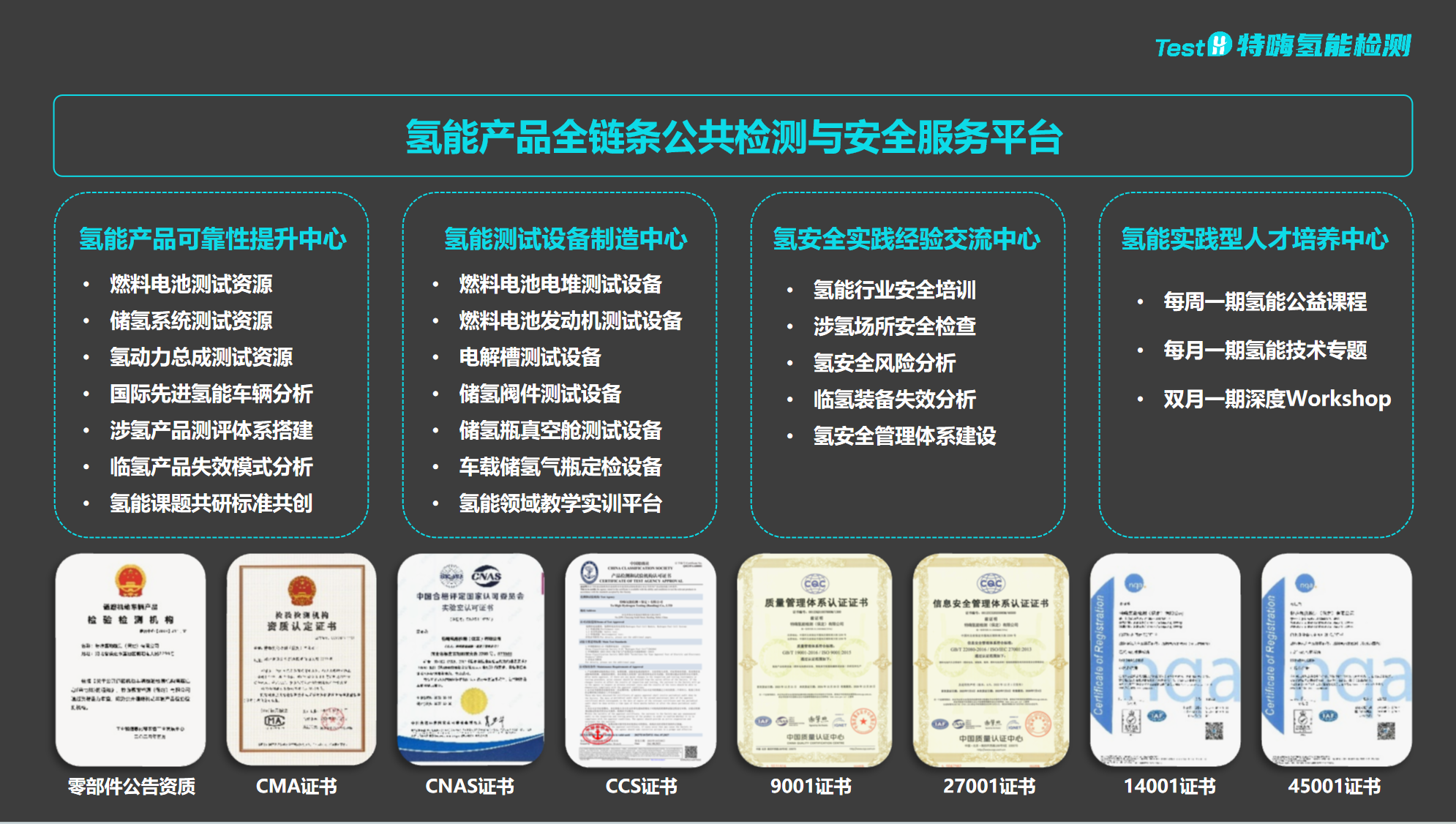

在院士科创发展.长城联合氢能测试报告基础上,

1,院士科创发展 可 根据企业需要 组织行业专家 针对问题 出具 问题分析解决 专家方案

2,院士科创发展 可 根据企业需要 联合海内外相关检测机构 出具测试认证报告

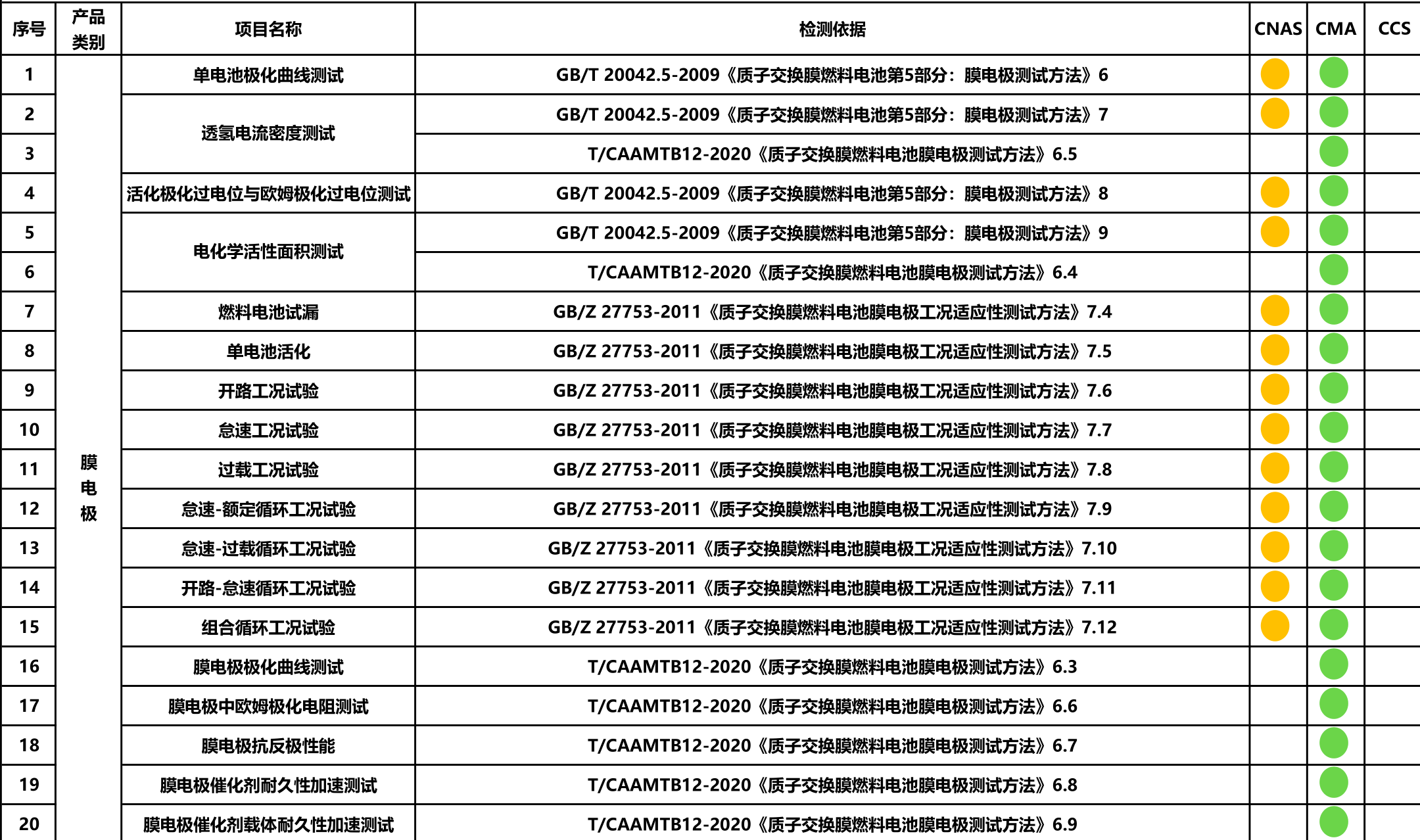

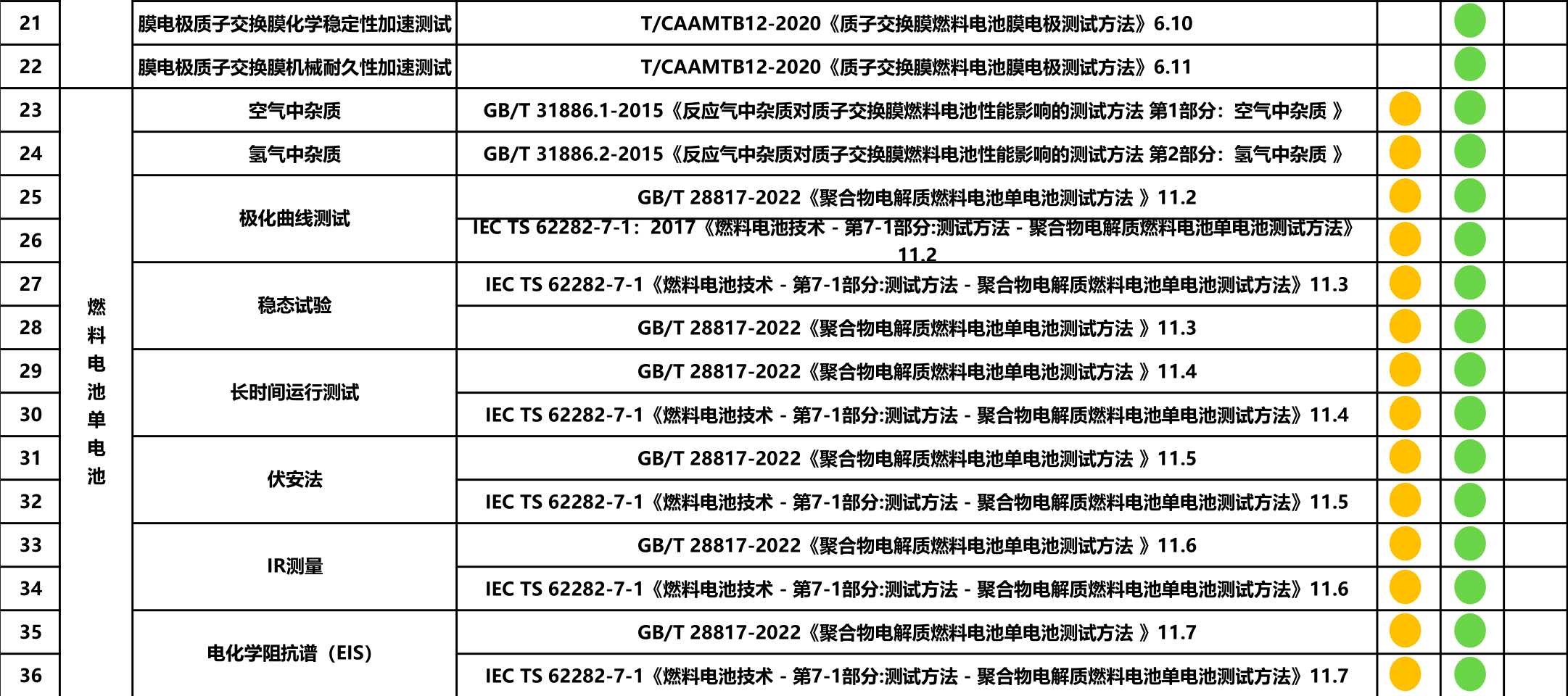

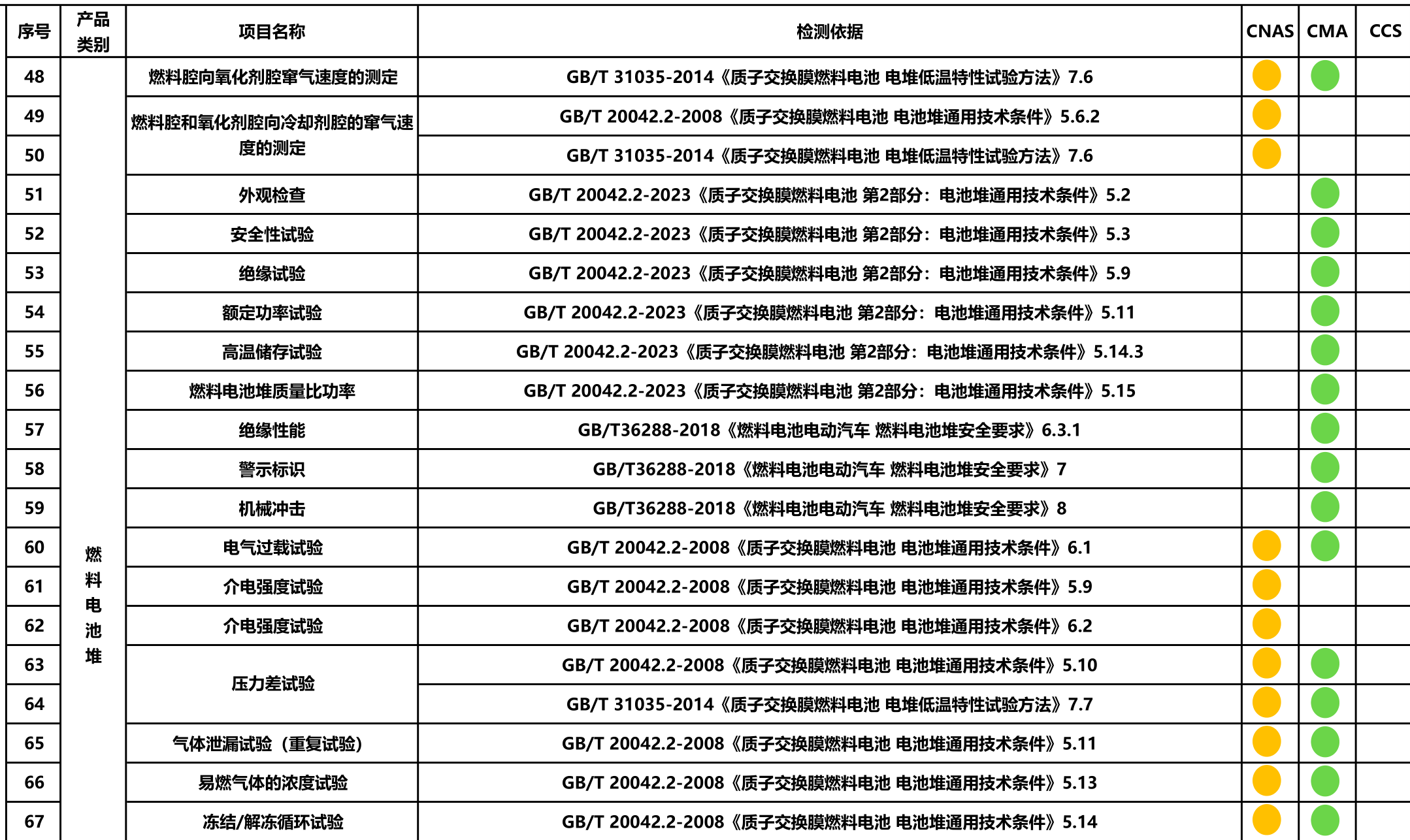

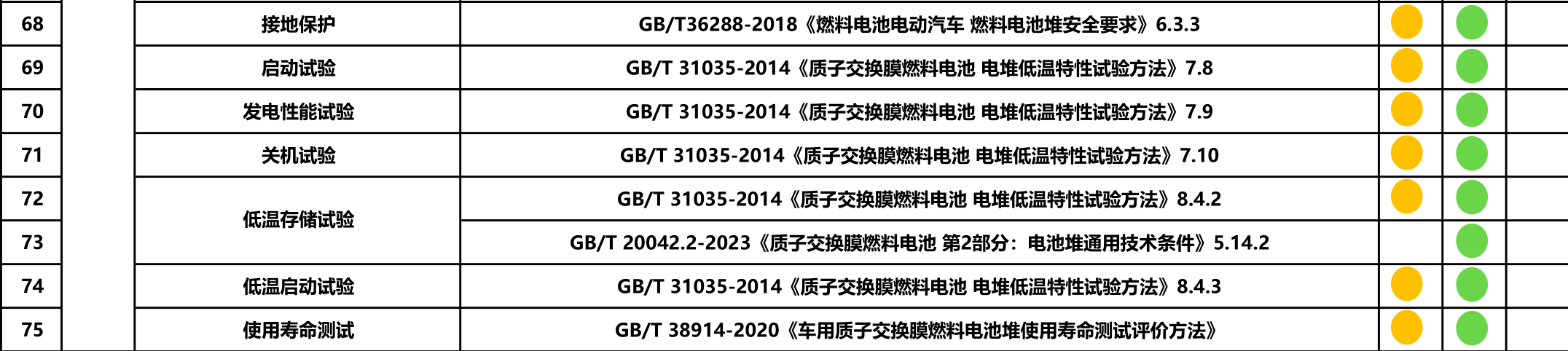

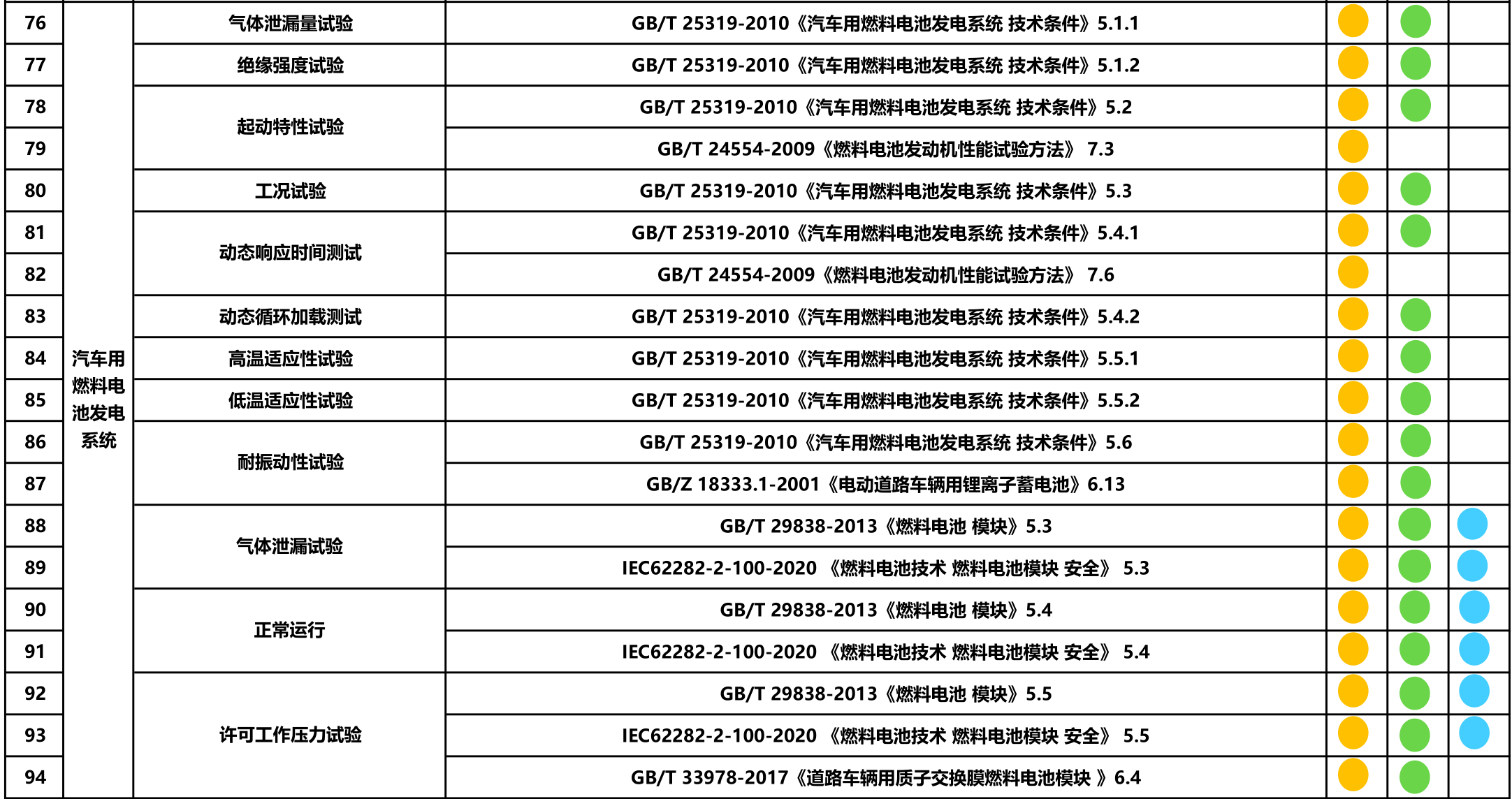

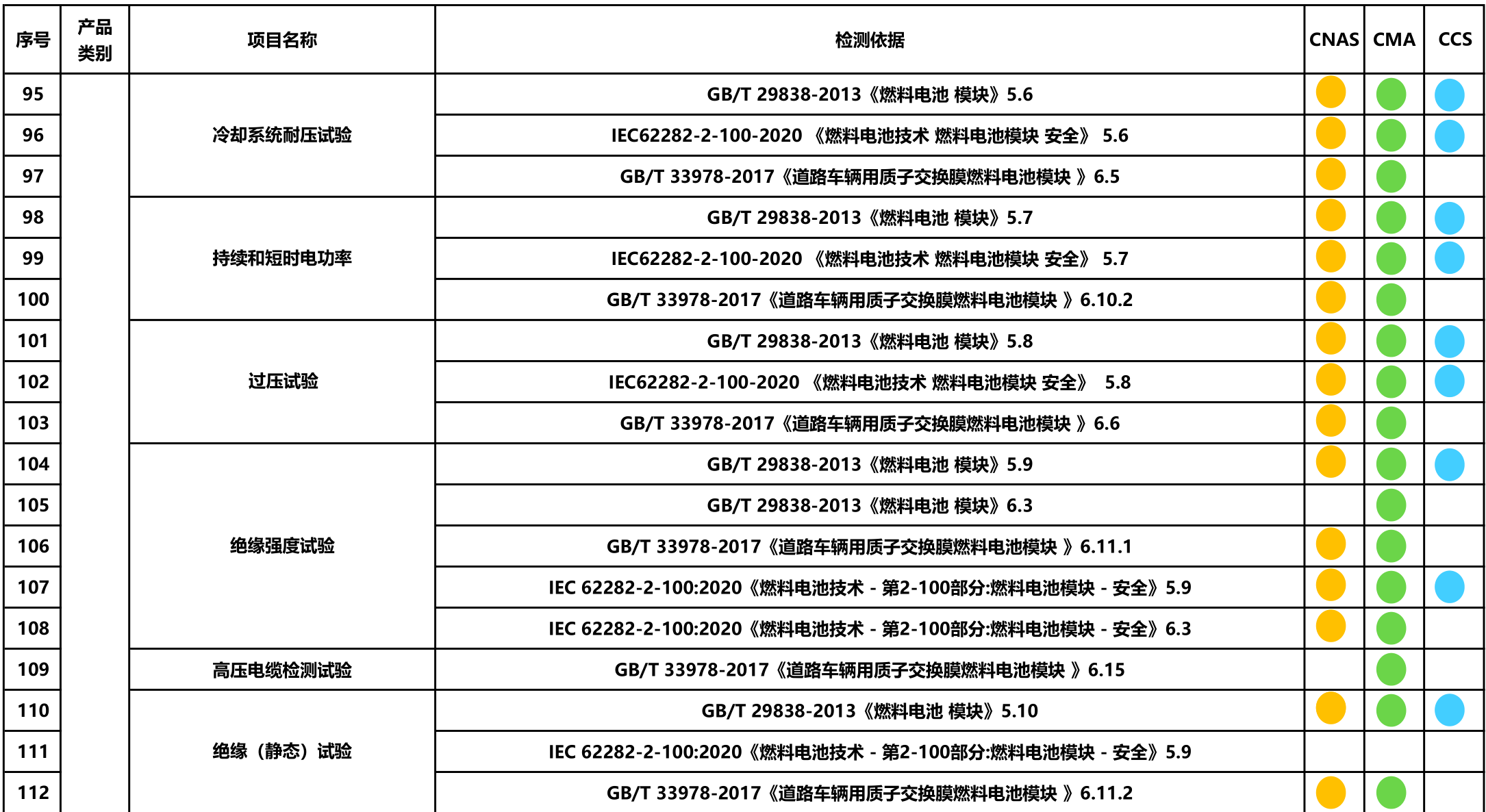

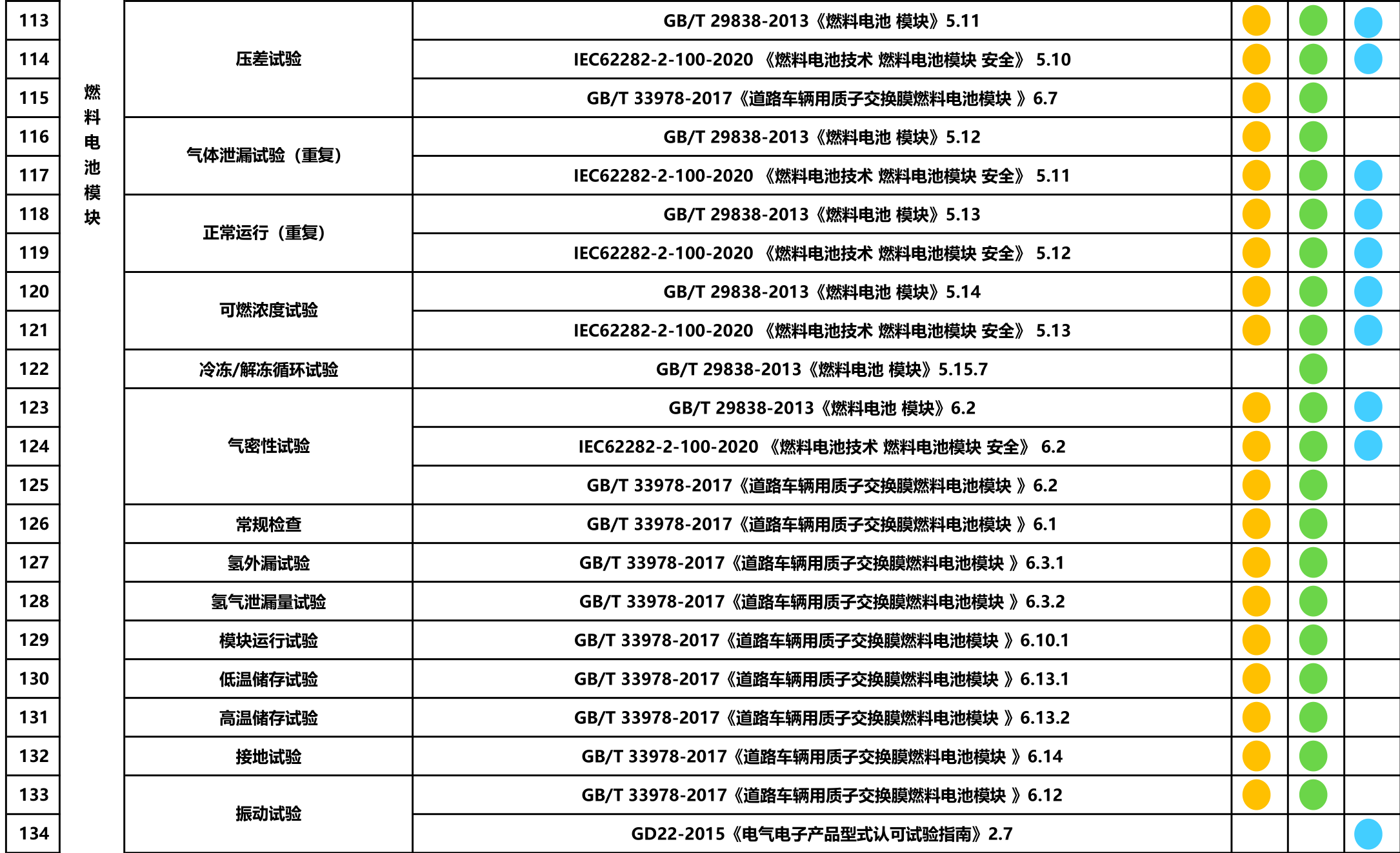

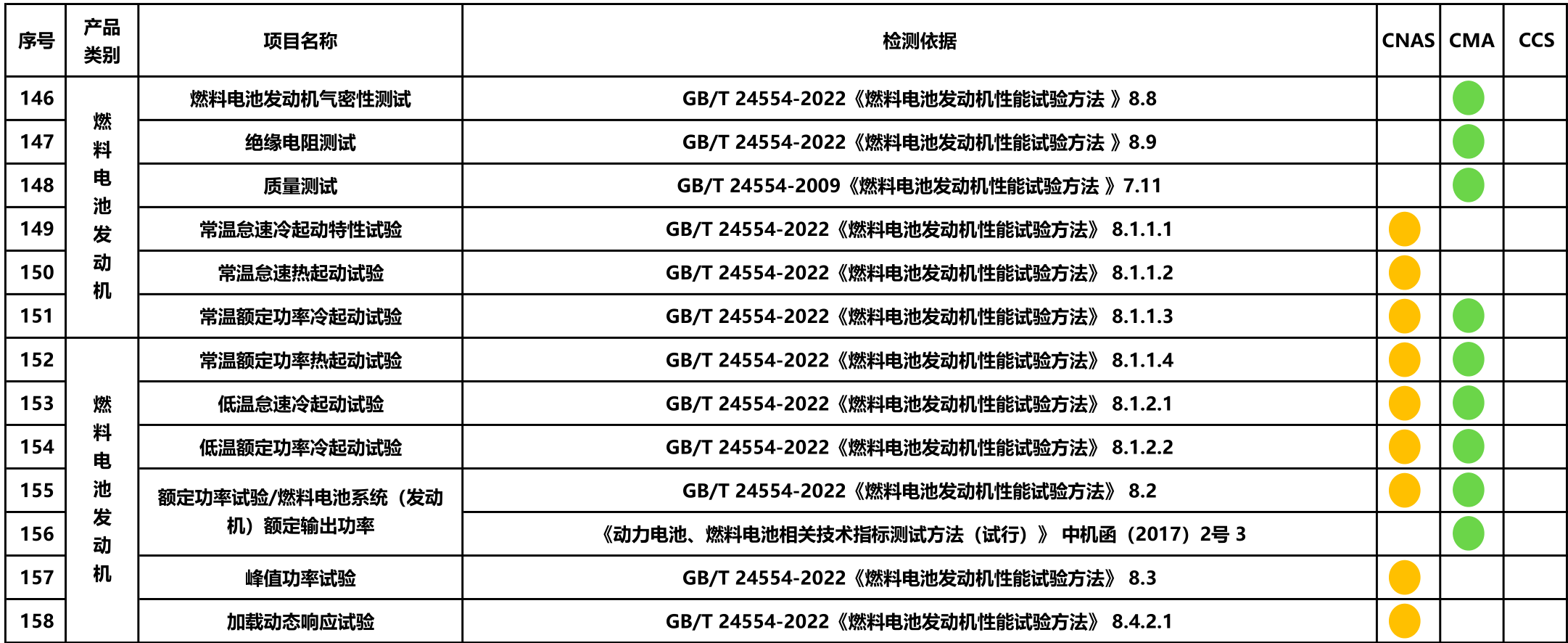

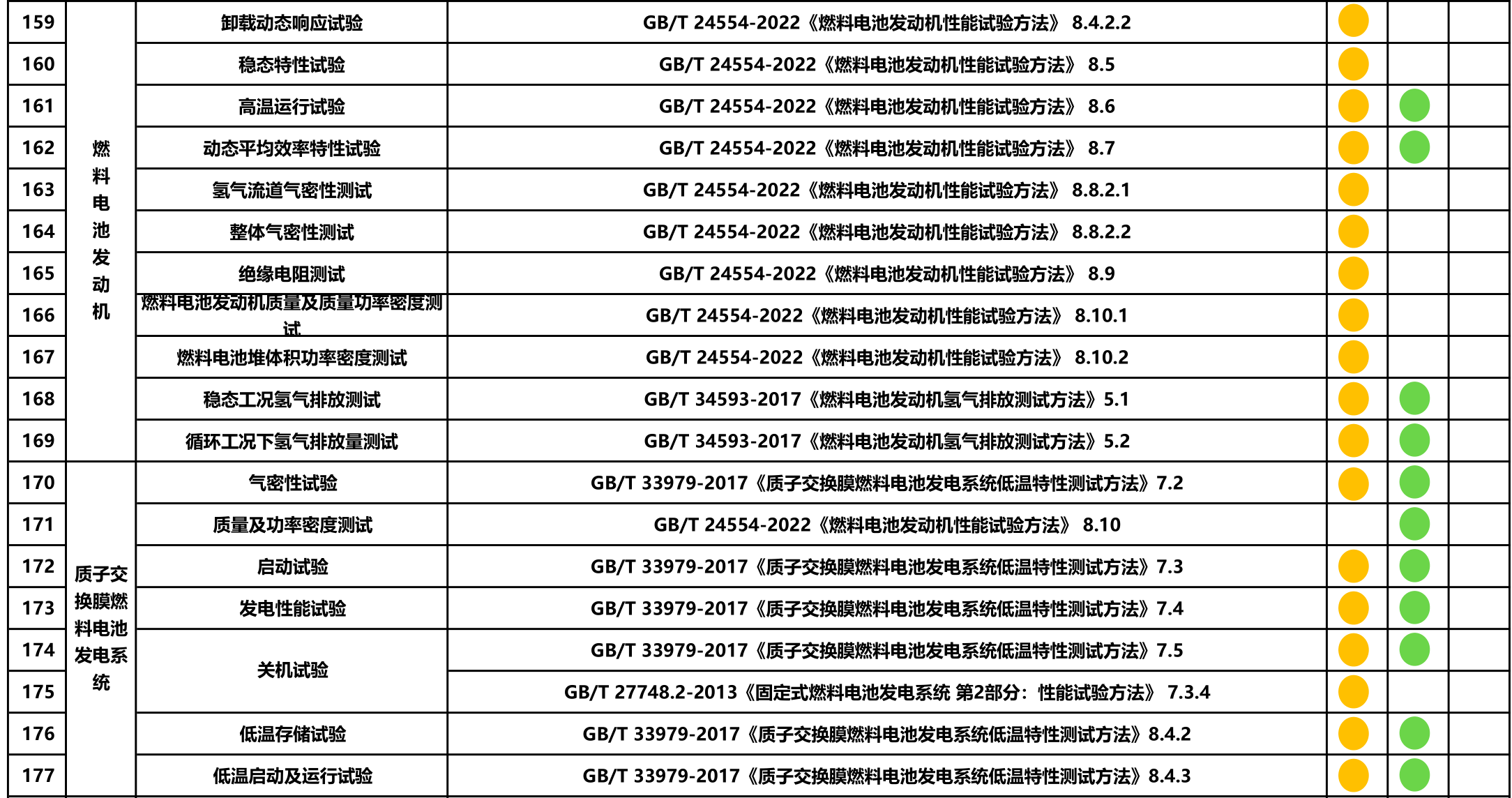

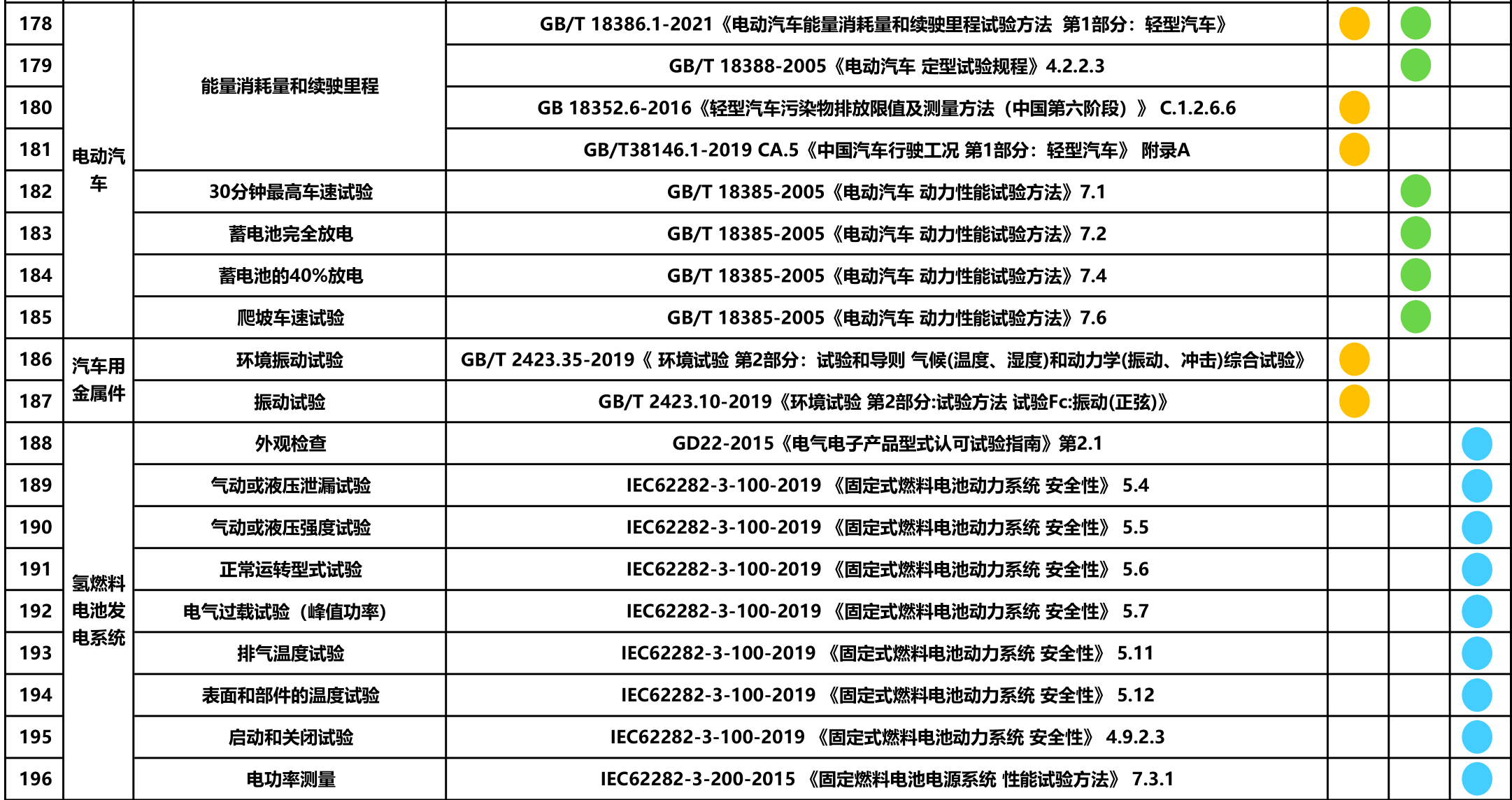

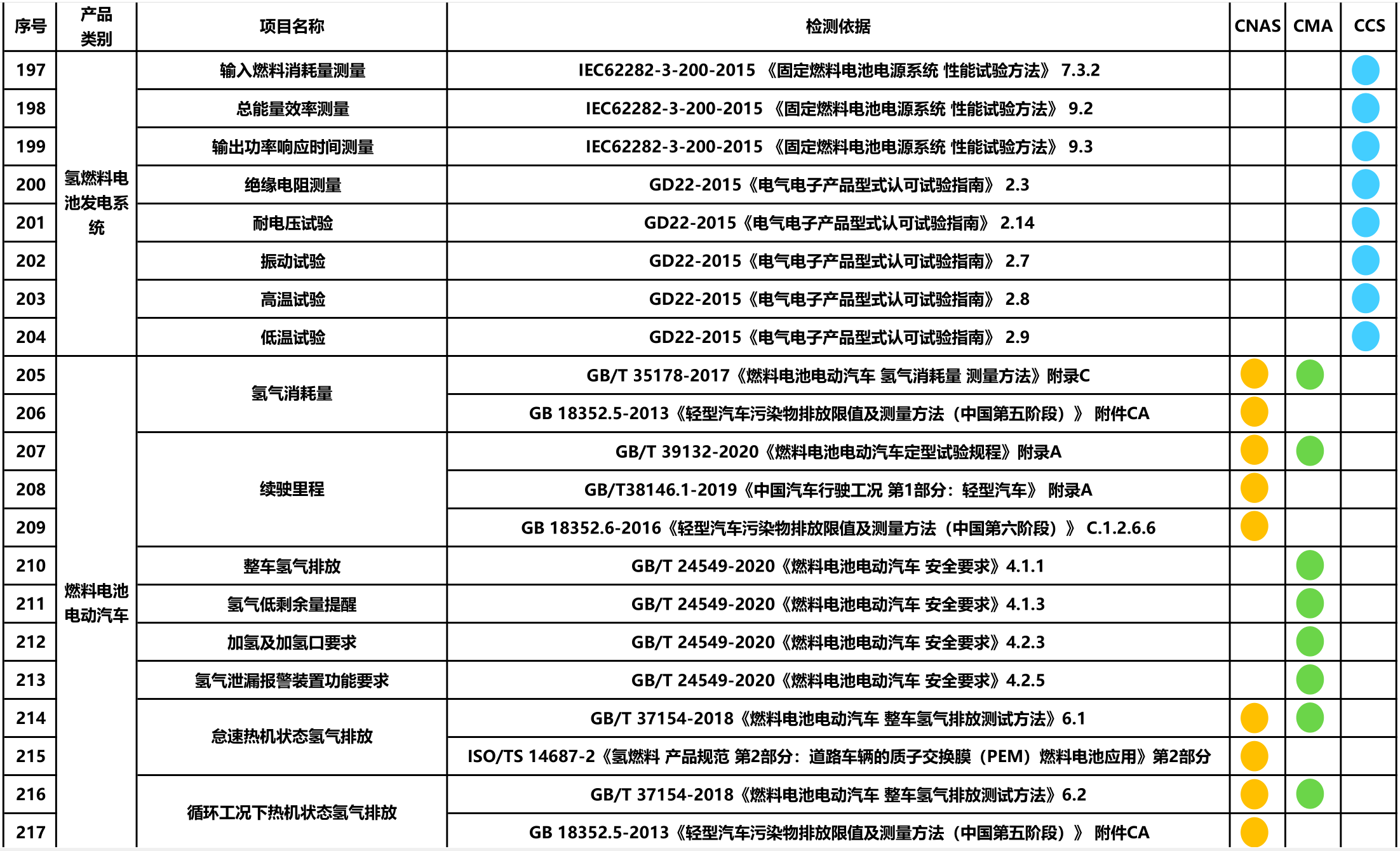

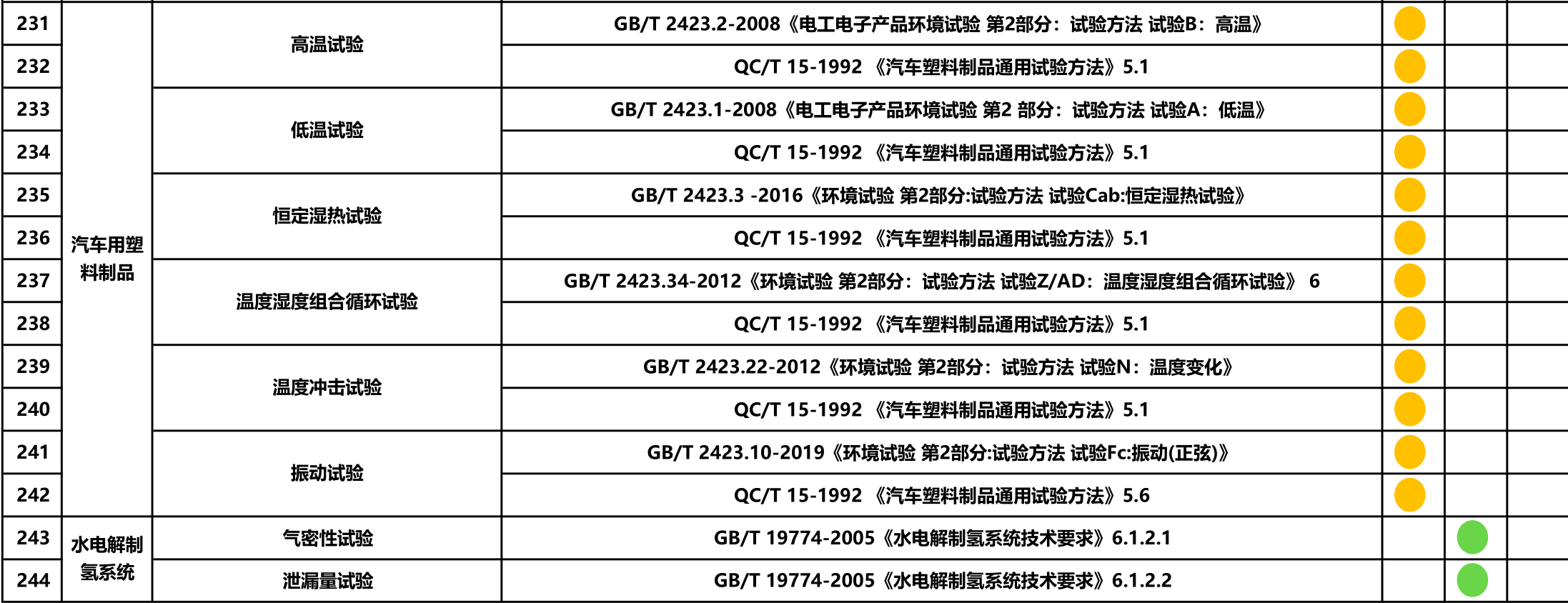

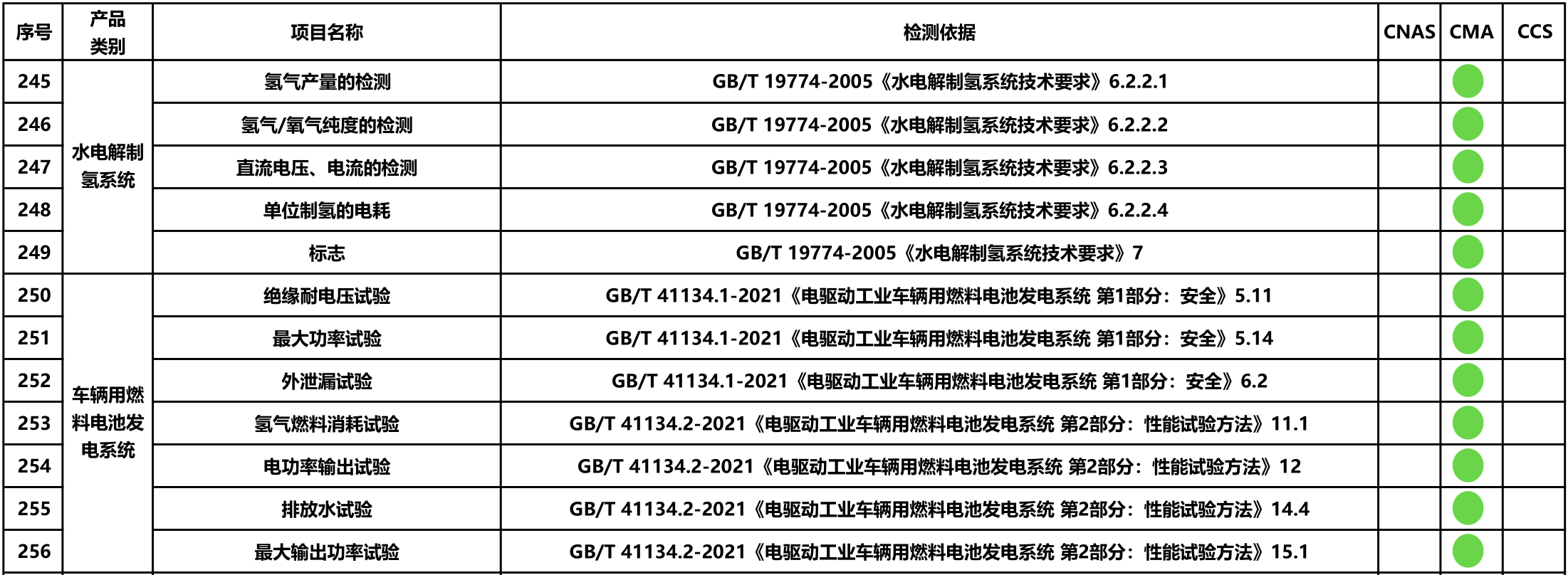

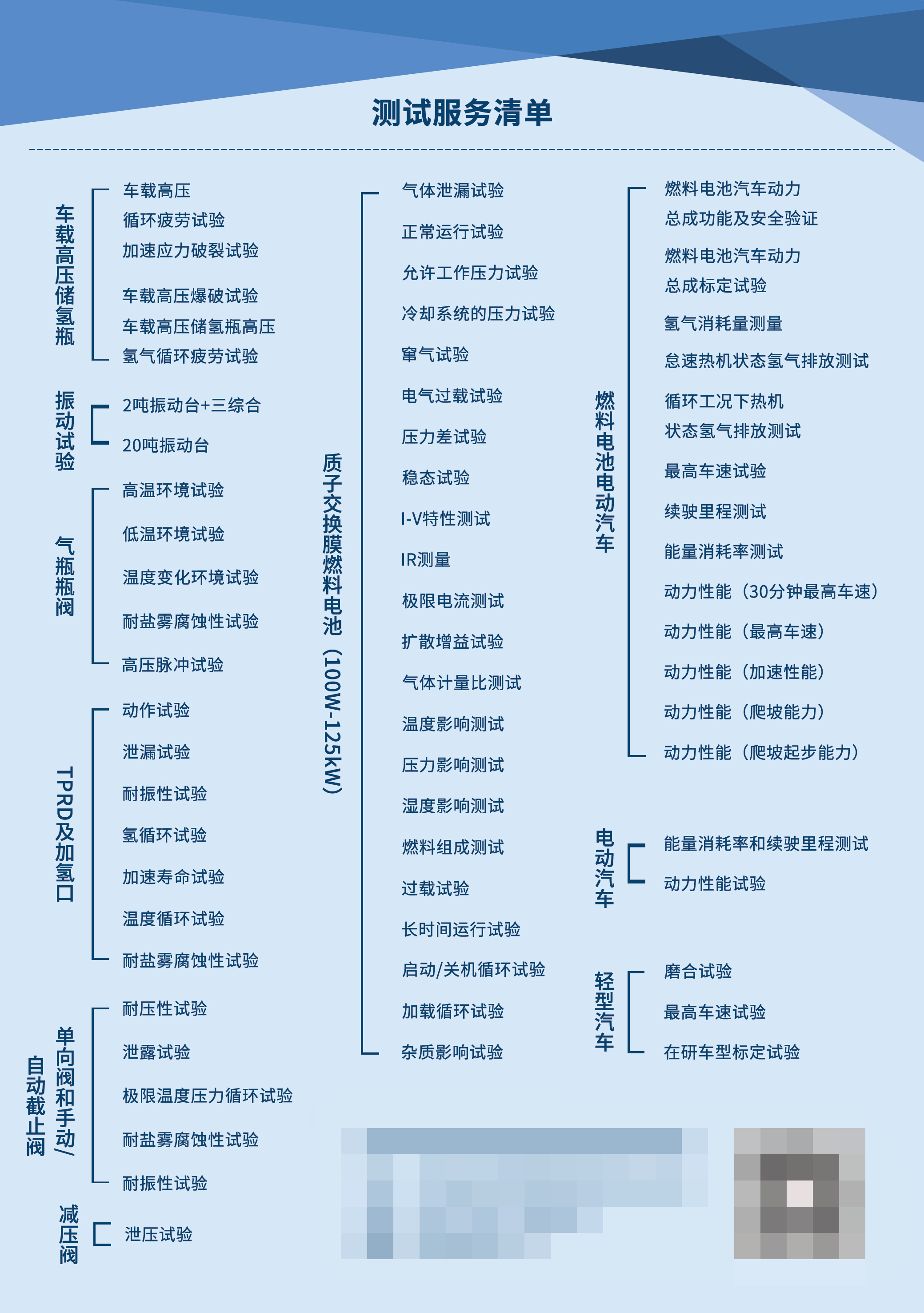

试验能力清单

检测需求表

联合氢能检测项目组

T: +86-13381813477

E: cccistic@163.com